Key Takeaways

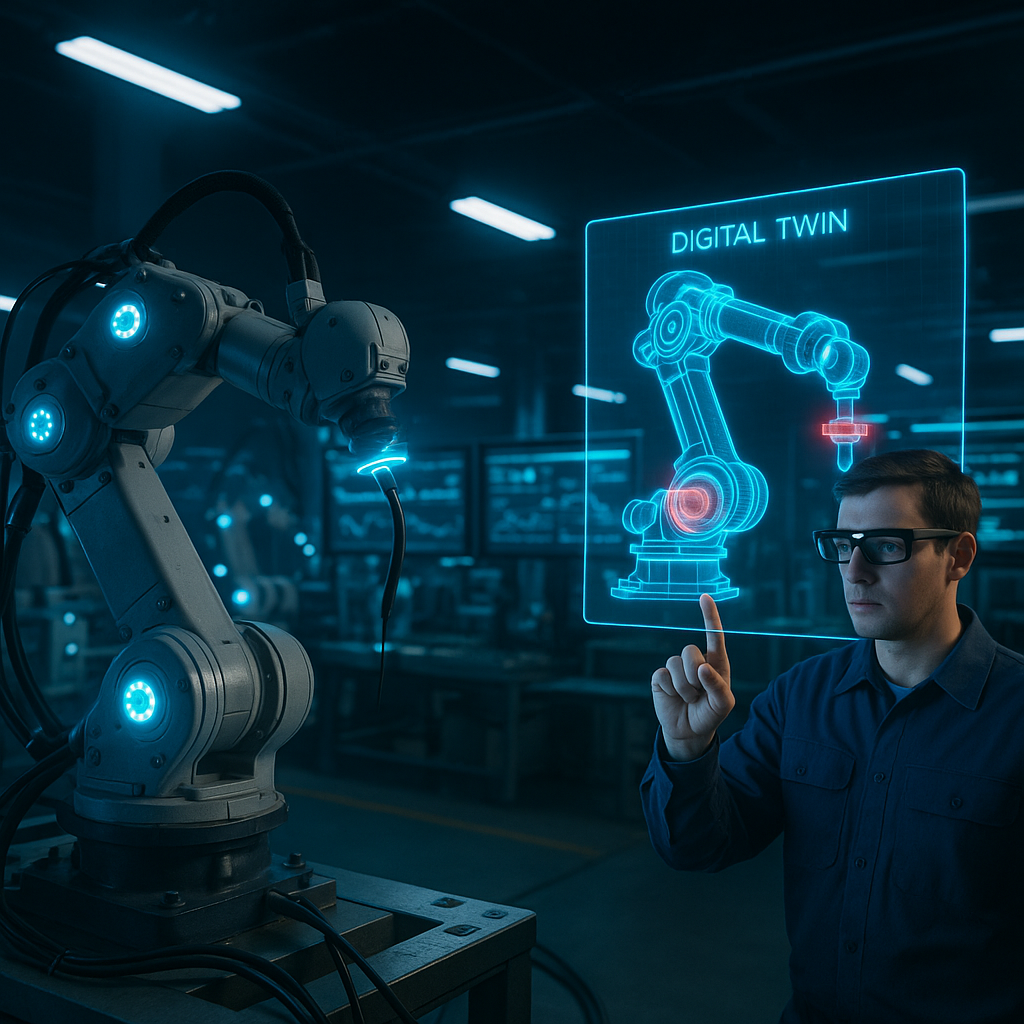

Digital twin AI is transforming the way manufacturers maintain and optimize their assets by merging virtual replicas, IoT connectivity, and real-time analytics. This convergence enables organizations to forecast equipment failures instead of simply reacting to them. It is catalyzing a new era of efficiency and resilience across a wide range of industries. As predictive maintenance evolves, the integration of advanced modeling, data streams, and artificial intelligence is setting new standards for operational excellence.

Virtual replicas are revolutionizing asset monitoring. Digital twins move beyond traditional, static dashboards by providing dynamic, real-time views of physical assets. This continuous surveillance delivers nuanced insights, enabling a level of system understanding that legacy monitoring tools cannot match.

IoT sensors provide a constant stream of actionable insights. As vast sensor networks transmit real-time data, digital twins interpret subtle fluctuations in vibration, temperature, and usage patterns, building rich datasets that drive predictive AI models.

AI redefines the maintenance paradigm. Machine learning algorithms, embedded in digital twins, forecast potential failures before escalation occurs. This transforms emergency repairs into planned, data-driven interventions that minimize costs and disruptions.

Stay Sharp. Stay Ahead.

Join our Telegram Channel for exclusive content, real insights,

engage with us and other members and get access to

insider updates, early news and top insights.

Join the Channel

Join the Channel

IT-OT convergence is accelerating. Quietly reshaping not just the factory floor but also software and IT infrastructure, digital twin AI bridges operational technology with information technology. This unified approach fosters holistic system reliability and paves the way for smarter maintenance practices.

Integration challenges require strategic data stewardship. Implementing digital twins demands harmonizing new and legacy data sources, ensuring interoperability, and proactively addressing cybersecurity risks in an increasingly interconnected environment.

Predictive maintenance delivers measurable ROI. Manufacturers deploying digital twin AI report major reductions in unplanned downtime, extended equipment life cycles, and optimized utilization of both assets and human resources. These improvements directly translate into financial gains and competitive advantage.

Industry 4.0 expands horizons of resilience and adaptability. Digital twin-enabled predictive maintenance exemplifies the adaptability and continuous improvement ethos central to Industry 4.0. Organizations are building systems that not only anticipate failures but evolve to meet new challenges, across sectors ranging from automotive and pharmaceuticals to energy, healthcare, and beyond.

In the following sections, we will explore the core technologies underpinning digital twin AI, outline practical strategies for successful implementation, and dissect the far-reaching implications for businesses seeking to stay ahead of asset failures in a digitally connected world.

Introduction

Machine failures rarely announce their arrival. Instead, they strike with little warning, bring production to a grinding halt, and erode profit margins in the process. Digital twin AI fundamentally alters this narrative by harnessing virtual replicas, IoT connectivity, and real-time analytics to make machinery behavior visible and predictable. By creating a digital model of each asset (a living, evolving twin), manufacturers can observe subtle shifts in temperature, vibration, and performance long before they escalate into crises.

This transition marks more than an incremental improvement. It is a dramatic shift from reactive maintenance to AI-driven, predictive strategies that use machine learning models to anticipate equipment failures and schedule interventions proactively. As digital twin technology merges with advanced manufacturing AI, Industry 4.0 moves from theory to tangible results: enhanced uptime, optimal resource use, and significant operational gains for maintenance professionals.

To fully grasp the transformative potential of digital twin AI, it is critical to understand how virtual models, data streams, and algorithmic intelligence come together to enable unprecedented resilience. The following sections break down the technologies, best practices, and broader strategies that successful organizations are leveraging to redefine the future of maintenance.

Understanding Digital Twin Technology in Manufacturing

Digital twin technology represents a profound evolution in how physical assets are managed. It involves constructing a comprehensive, virtual counterpart to a physical manufacturing asset by merging real-time sensor data with sophisticated simulation models. This approach enables organizations to mirror real-world conditions, behaviors, and performance characteristics with extraordinary fidelity, providing a holistic view of operational health.

Today’s digital twins harness AI not only to process immense volumes of operational data, but also to learn from it. This intelligence enables prediction of failures, identification of evolving issues, and continuous optimization of asset performance.

The architectural foundation of manufacturing digital twins rests on three interconnected layers:

- Physical Layer: Real-world assets outfitted with IoT sensors and data acquisition systems

- Digital Layer: Virtual models that absorb and interpret continuous data flows

- Integration Layer: AI and machine learning frameworks that analyze patterns, predict outcomes, and prescribe maintenance actions

Key Components of Digital Twin Systems

Robust digital twin platforms rely on several essential building blocks working cohesively. High-precision sensors track operational parameters such as temperature, vibration, pressure, and electrical load. Edge devices aggregate and pre-process data at the source, while cloud infrastructures manage deep analytics and long-term model evolution.

For effective real-world deployment, digital twin maintenance systems demand:

- IoT sensors with high fidelity and appropriate sampling frequency

- Reliable, high-bandwidth data transmission channels (wired and wireless)

- Scalable and secure cloud or on-premise storage for detailed historical data

- Agile, real-time analytics engines for rapid response and forecasting

- Seamless integration hooks for linking with existing manufacturing software and hardware systems

This integrated environment provides both a microscopic and macroscopic view, allowing teams to zoom in on a specific anomaly or assess wider operational trends across entire facilities.

AI-Driven Predictive Analytics Integration

The true intelligence of digital twins lies in their ability to interpret data through advanced algorithms. Manufacturing-focused AI models within digital twins leverage machine learning techniques to detect early warning signals, often hidden in the noise, for a range of failure modes.

Digital twins typically employ a strategic blend of the following approaches:

Stay Sharp. Stay Ahead.

Join our Telegram Channel for exclusive content, real insights,

engage with us and other members and get access to

insider updates, early news and top insights.

Join the Channel

Join the Channel

- Anomaly detection models highlight deviations from baseline patterns, signaling emerging faults.

- Classification algorithms identify and categorize equipment issues, streamlining root cause analysis.

- Regression models predict the estimated time to failure or necessary interventions.

- Deep learning techniques interpret multivariate sensor data, revealing interactions invisible to traditional analytics.

Advanced Pattern Recognition Capabilities

Modern implementations, including those in high-stakes settings like aerospace, pharmaceuticals, and energy plants, use neural networks adept at exposing intricate relationships within operational data. For instance, an automotive manufacturer documented a 35% reduction in unexpected downtime after introducing AI-driven digital twins that could alert maintenance teams to early-stage bearing failures, weeks before physical symptoms appeared. In the healthcare sector, digital twins are beginning to power predictive equipment maintenance in hospital settings, minimizing disruptions in critical medical services.

Similarly, in the utilities sector, energy companies deploy digital twins to monitor grid infrastructure, preempt equipment overloads, and prevent large-scale outages. By extending applications beyond the factory floor, digital twins are showing their capability in fields as diverse as transportation, logistics, and environmental systems management.

Real-Time Monitoring and Analysis

Continuous monitoring forms the backbone of digital twin-based failure prediction. Modern systems operate 24/7, assimilating and analyzing torrents of data to deliver actionable insights immediately.

Sensor Data Processing

- Continuous acquisition of real-world parameters via distributed sensor networks

- Automated data validation and cleansing to eliminate anomalies and errors

- Edge computing architectures provide near-instantaneous feedback

- High-volume data streams funneled to the cloud for deeper, retrospective analysis

Performance Analysis

Digital twins offer real-time benchmarks by comparing operational states against historical and theoretical models. This enables:

- Timely detection of performance drops and emerging trends

- Early identification of inefficiencies and losses

- Predictive modeling of upcoming maintenance needs

- Continuous tuning of operational parameters for optimal throughput

In addition to manufacturing, this real-time performance insight is fueling smarter maintenance in industries such as transportation, where predictive digital twins forecast rail and aviation maintenance demands, and in smart city infrastructure, optimizing traffic signals and facility operations.

Predictive Maintenance Implementation

Achieving true predictive maintenance with digital twins requires meticulous planning on both technical and organizational fronts. The process starts with data (both historical and real-time) and hinges on seamless integration with business-critical systems.

Data Requirements

To feed predictive models effectively, organizations prioritize collecting:

- Historical maintenance logs and intervention records

- Detailed asset specifications and manufacturer data

- Operational context, including usage rates and environmental conditions

- Production and scheduling data that impact wear and tear

System Integration

For holistic insight, digital twins must bridge disparate systems, including:

- Supervisory Control and Data Acquisition (SCADA) frameworks

- Enterprise asset management software

- Production planning, scheduling, and quality control platforms

- Maintenance management tools

This interconnected approach ensures that predictive insights trigger the right actions automatically, refining maintenance schedules and resource allocation dynamically.

Benefits and ROI Analysis

Across industries, digital twin-enabled predictive maintenance delivers transformative results. Recent market studies have quantified the payoff:

- Maintenance costs drop by 25-30%, as repairs are planned rather than emergency-driven

- Unplanned equipment downtime decreases by up to 75%

- Asset lifecycles extend by as much as 25%

- Overall equipment effectiveness may rise by 15-20%

Cost-Benefit Considerations

Implementing digital twins requires careful budgeting, but the operational and financial gains frequently outweigh upfront expenditures:

- Upfront investments: Sensors, cloud infrastructure, platform licenses, integration services

- Ongoing expenses: Storage, computation, analytics, ongoing calibration

- Tangible returns: Eliminated production halts, reduced overtime costs, prolonged asset utility, and fewer catastrophic failures

It is crucial for organizations to tailor deployment to their specific context. For example, a leading pharmaceutical manufacturer recouped investment within 18 months by using digital twins to cut maintenance-related production losses nearly in half. In the utilities sector, companies are seeing similar returns by minimizing outage events and overflow situations through intelligent asset monitoring.

Healthcare providers utilizing predictive maintenance for critical hospital equipment (such as MRI machines and sterilization systems) achieve both patient safety gains and significant operational cost reductions. Retail and logistics operators, meanwhile, apply digital twins to elevate uptime and efficiency of fulfillment automation, boosting their ability to meet surges in customer demand.

Challenges and Solutions

Every innovation journey faces obstacles, and digital twin deployments are no exception. Key challenges include both technical and change management dimensions.

Technical Challenges

- Ensuring consistent, high-quality data collection from all assets and locations

- Integrating new digital twin systems with entrenched legacy platforms and standards

- Strategically placing, calibrating, and securing sensor networks for reliable coverage

- Sustaining AI model accuracy as conditions and asset profiles evolve

Operational Challenges

- Upskilling maintenance and IT teams for advanced analytics and AI tools

- Managing resistance to workflow changes across departments

- Aligning predictive maintenance with established procedures and production cycles

- Rigorous validation of system predictions to build organizational trust

Organizations have overcome these hurdles by adopting phased rollouts. Beginning with pilot projects that demonstrate value, then scaling cautiously. Ongoing employee training, transparent communication, clear success metrics, and disciplined optimization cycles form the foundation of successful long-term adoption.

Conclusion

The convergence of digital twin technology and AI-powered analytics marks a watershed moment for predictive maintenance, unlocking new levels of insight and control for asset management. By integrating high-resolution sensor data, advanced simulation, and real-time intelligence, industries gain the unprecedented ability to anticipate breakdowns, optimize maintenance strategies, and extend asset lifespans well beyond previous limits. These capabilities are reshaping operational benchmarks in manufacturing, healthcare, energy, logistics, and beyond.

Realizing these benefits, however, is not a matter of technology alone. It calls for resilient data practices, seamless system integration, strategic investment in people and infrastructure, and a willingness to adapt culturally. Forward-looking businesses recognize: digital twins are not merely tools for preventing breakdowns, but strategic levers for achieving greater resilience, efficiency, and competitive differentiation.

Looking ahead, organizations across sectors that embrace a future-oriented mindset (grounded in adaptability, continual learning, and the intelligent use of data) will define the next chapter of operational excellence. The transformative potential of digital twins is clear. The challenge now lies in harnessing them not just to anticipate failure, but to set new standards of productivity, innovation, and readiness for whatever the future holds.

digital twin technology

AI and machine learning frameworks

operational data

historical and theoretical models

Leave a Reply